Resin coating: technical details

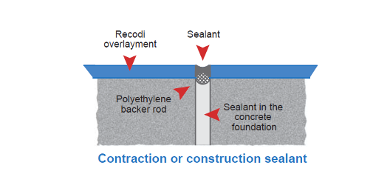

On a resin coating, it is standard practice to include all of the joints found in the underlying concrete flooring. When the resin coating is polymerized, the joints are cut and then immediately cleaned, removing any dust generated. A polyurethane-foam seal is then inserted at -5 mm before the joint is sealed with a bicomponent polyurethane formulation.

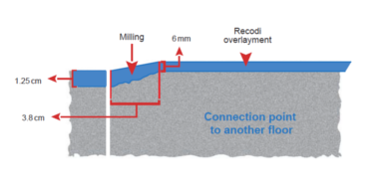

At the point where two floors of different types meet, the concrete floor – which serves as the foundation for the resin coating – is milled. The resin coating then applied. In this way, thanks to the milling, which strengthens the joint, the resin coating at the joint does not become detached from the foundations even when subject to the continual transit of pallet trucks and fork-lift trucks.

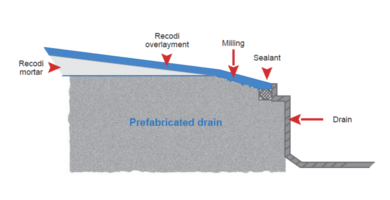

In production plants and within food-processing and pharmaceutical companies, the floors are usually equipped with water-drainage channels. It is essential manage the connection between the floor and the channel, since they are made from different materials. The concrete floor, which constitutes the foundation, is milled near the connection point. The resin coating is applied and, at the point where the floor and the channel meet, a joint is made into which a polyurethane-foam seal is inserted and then sealed with a bicomponent polyurethane formulation. With this reinforcing treatment, the resin coating does not become detached from the at the point which it joins with the channel, and there is no water infiltration.